¶ Initial v1.0 support in v1.0.127, v1.1 support in v1.0.134

¶ Features

- Integrates as “CANTCU" peripheral through CAN-bus (v1.1)

- Integrates as an “External gearbox controller” through CAN-bus (v1.0)

- Fully customizable control strategies for cuts/blips in MaxxECU

- WheelSpeed input from CANTCU to MaxxECU (8HP transmissions)

¶ Connection

- CANTCU CAN3 is connected to the MaxxECU CAN-bus.

- CAN Speed is configurable

- CAN2.0B, Standard 11bit identifiers

- All 16 bit values are Little Endian

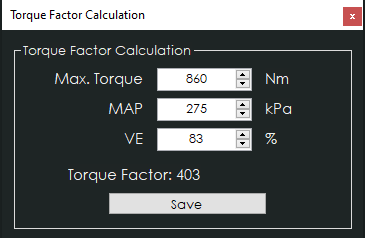

¶ Torque Factor (CANTCU)

To achieve a somewhat realistic torque estimation, the VE (fuel) table needs to be tuned and MaxxECU correctly configured to show real-world VE values (Multiply Lambda). For this torque estimation we use a Torque Factor. The torque factor is generated from engine running values taken from a single point of running (usually maximum measured torque on a dyno run). The values needed for calculation are listed below.

- Maximum Engine Torque (Nm)

- Manifold Absolute Pressure, MAP (kPa)

- Volumetric Efficiency, VE, Fuel Table (%)

Entering these values in the calculation window will generate a torque factor, which will be used as a baseline for torque calculations in the CANTCU.

Example of a calculated torque factor

¶ WheelSpeed input to MaxxECU (8HP)

If using Simulated WheelSpeed in CANTCU, the WheelSpeed is broadcasted from CANTCU to MaxxECU. Be sure to select “CAN-bus” as Speed source under Speed/Gear in MTune.

¶ Integration

NOTE!

All tuning should always be done by a professional in safe environment (track/dyno)

Before activating the blip function, it’s recommended to test downshifting and verify (realtime or logging) that the user table is behaving correctly during the blip. Starting values for tuning the blip should be low and gradually increased to avoid overrevving and undesired behavior/acceleration during the shift.

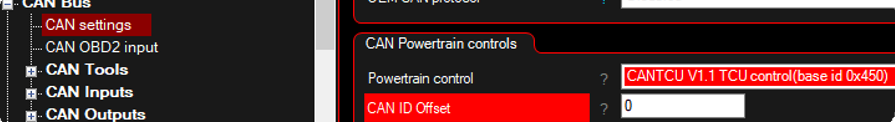

¶ MaxxECU Configuration

- CANTCU V1.1 needs to be selected in the CAN Powertrain controls.

¶ CANTCU Configuration

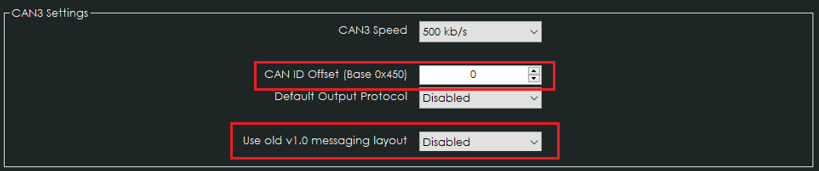

- Match the CAN ID Offsets in both CANTCU and MaxxECU configurations

Available Realtime-values in CANTCU (sent from MaxxECU)

| Engine RPM |

| TPS Value |

| Engine MAP |

| Wheel Speeds |

| Brake Switch |

| Coolant Temperature |

| Engine Oil Temperature |

Available Realtime-values in MaxxECU (sent from CANTCU)

| VSS Gear |

| Gearbox Mode |

| Gearbox Oil Temperature |

| Gearbox Calc Engine Torque |

| Gearbox Engine Target Torque |

| Shiftcut (0/1) |

| Blip (0/1) |

| Clutch Slip % |

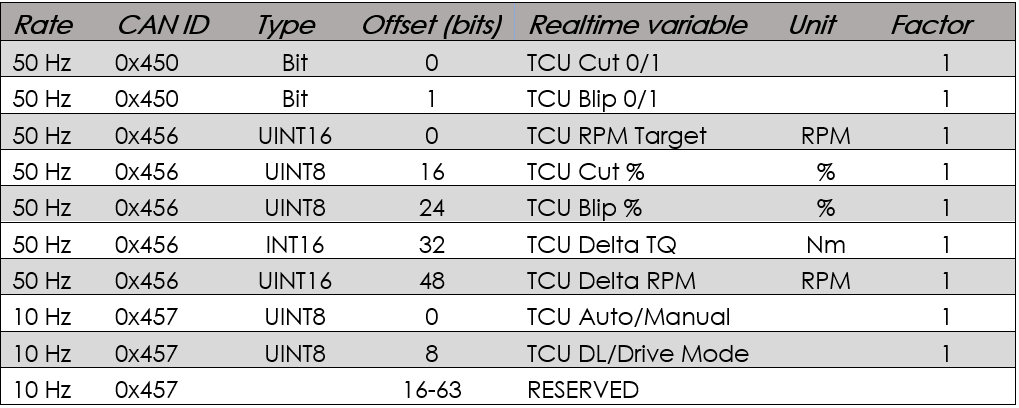

Extra values sent on the CAN-bus from CANTCU to aid configuration

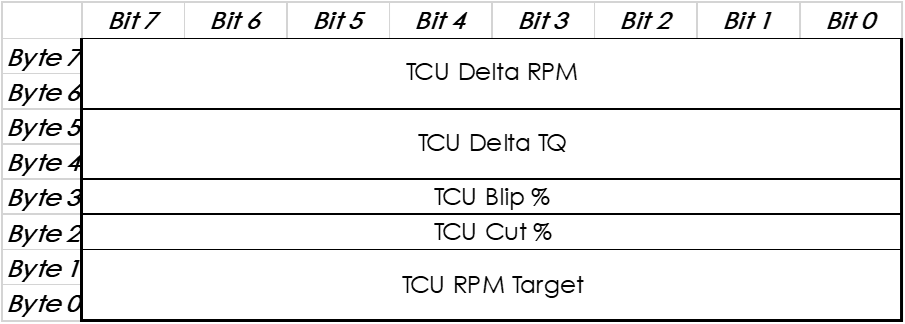

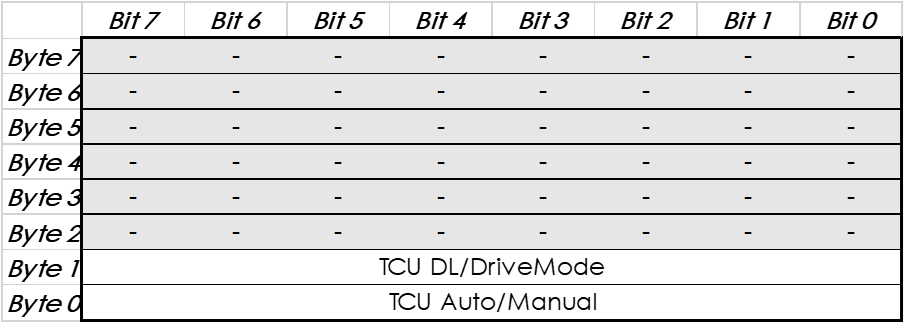

CAN-ID 0x456h

CAN-ID 0x457h

¶ Configuring Extra Values (CAN Inputs)

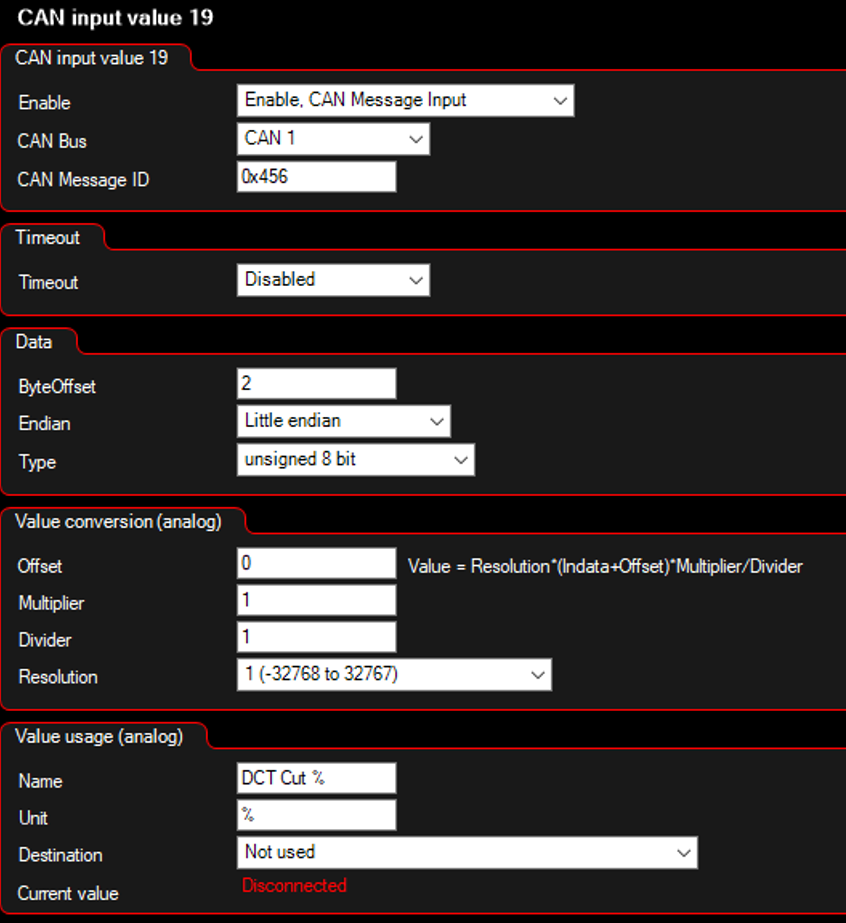

Extra values sent from CANTCU can be imported into MaxxECU by using the CAN Inputs. All the parameters needed for successful configuration of the extra values can be found in the tables shown on this page.

An example of configuring the extra value Cut % on a CAN Input:

¶ Tuning - Shiftcut

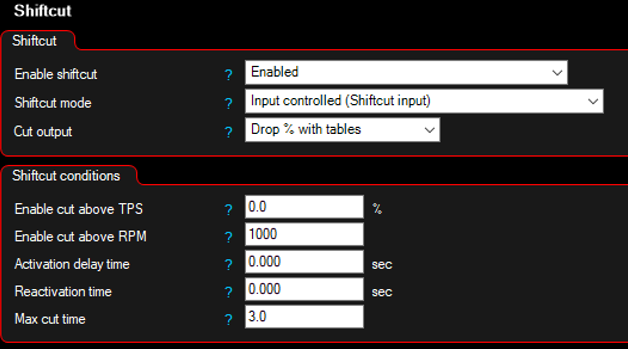

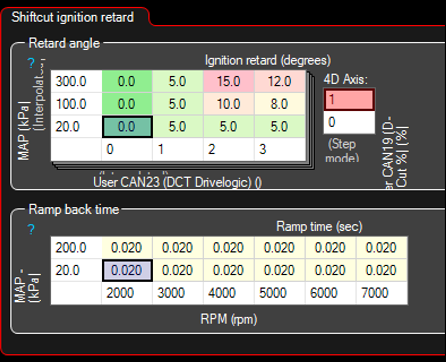

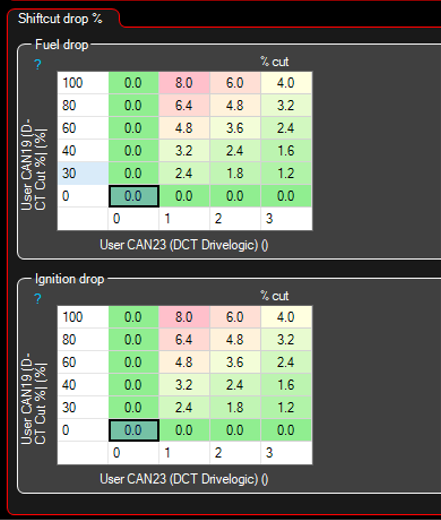

There are several ways of achieving a proper shiftcut. By default, CANTCU sends a shiftcut request (0/1) to MaxxECU Shiftcut Input. This request can be combined with the various extra values available like Cut %, Delta TQ, Delta RPM, Drive Mode etc. to get a nice and versatile cut that works optimally in every situation.

- MaxxECU Shiftcut Mode must be configured as “Input Controlled” to let CANTCU decide the duration of the cuts.

- Cut should be enabled also without throttle input and without any delays

Example configuration using F-Series DCT with cuts based on Cut % and DriveLogic Level from CAN Inputs

¶ Tuning - Blips

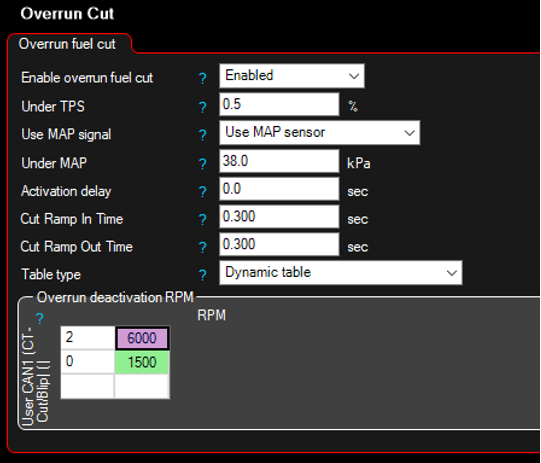

There are many strategies available for blipping the throttle. The best way to achieve sophisticated and optimally targeted blips is to continuously vary the throttle position throughout the blip process. This functionality can be achieved in MaxxECU by using a custom blip process instead of the default built-in function (Motorsport->Throttle Blip). For the custom blip process, a User Table and some extra values from CANTCU assigned to CAN inputs are needed.

To be able to do blips without the MaxxECU default blip function, the Overrun Cut (if enabled) needs to be configured to deactivate overrun fuel cut during CANTCU blip requests. This can be done by adding a table to the function, and defining the Overrun deactivation RPM to be higher than the maximum blip RPM (e.g. 6000RPM) when CANTCU blip request (CAN input value=2) is active. The other parameters like Activation delay and Cut Ramp In/Out Times may need some tweaking, but a configuration similar to the one below should provide a good starting point.

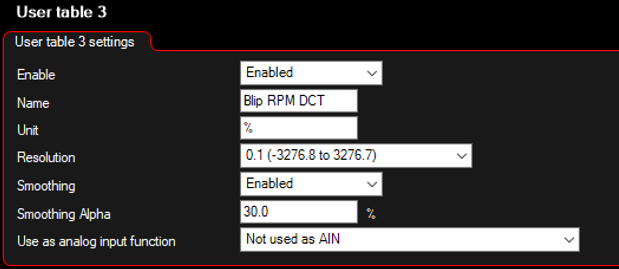

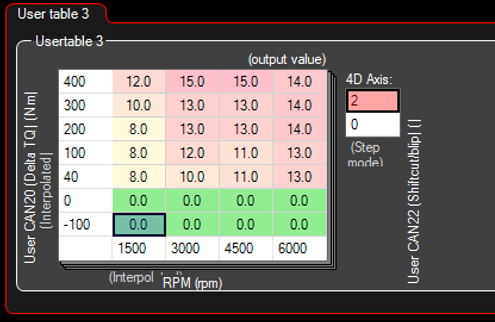

A free User Table needs to be enabled. The User Table settings can be configured freely. Using smoothing can help calm down throttle control oscillations if needed.

The User Table output is a percentage added to throttle position depending on various user-definable inputs. Delta TQ or Delta RPM combined with Engine RPM have been proven to work nicely, but basically any combination can be used, thanks to the freely configurable axes.

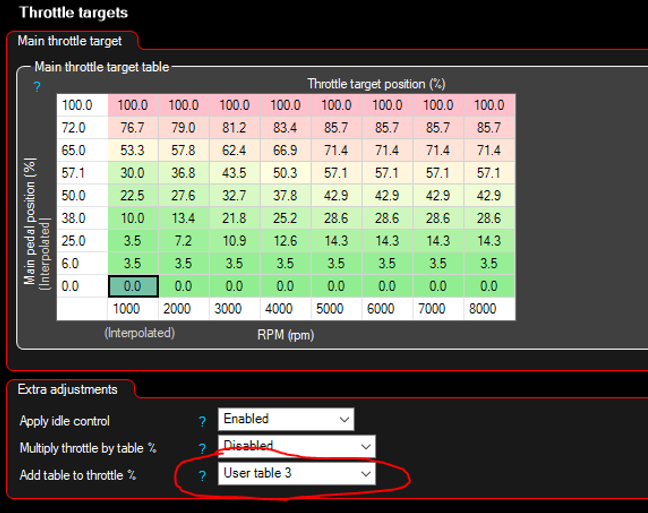

To activate the blip function, the User Table created earlier is added to Main Throttle Target (E-Throttle -> Throttle Targets).

¶ Resources

CANTCU-MaxxECU v1.1 PDF Manual

CANTCU-MaxxECU v1.0 (old) PDF Manual