¶ Initial support in v1.0.134

Supported ECUs: Delta 700,880, 900 and GDI6 ECUs (FW 01.06.2023 or newer)

¶ Features

- Uses SCS Delta Torque Estimation

- Cuts based on Torque Management -function

- Blips based on RPM Targeting from CANTCU

¶ Connection

CANTCU CAN3 is connected to SCS Delta CAN1 or CAN2.

- CAN2.0B, Standard 11bit identifiers

- CAN Speed is configurable

- CAN I/O Addressing is configurable

¶ Integration

NOTE!

All tuning should always be done by a professional in a safe environment (track/dyno)

RPM Targeting (blips) on downshifts needs to be carefully tuned to avoid undesired behavior (overshoot/undershoot) of the blip. Especially on DCT transmissions, the RPM request sent from CANTCU to SCS Delta is heavily dependent on a correctly calibrated diff ratio/wheelspeed.

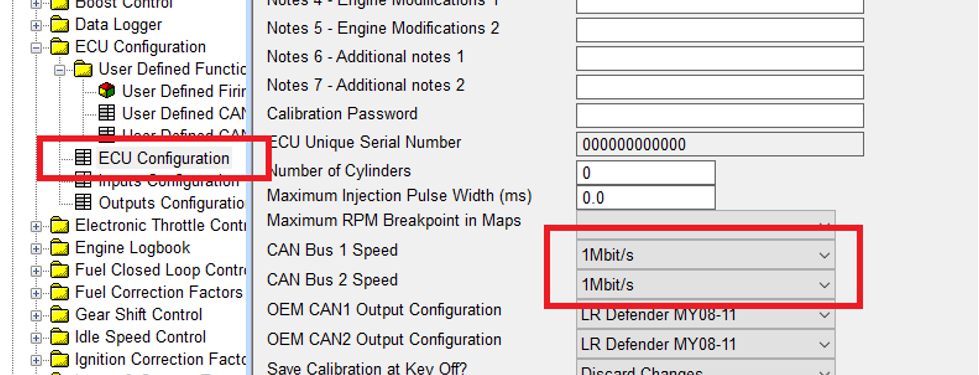

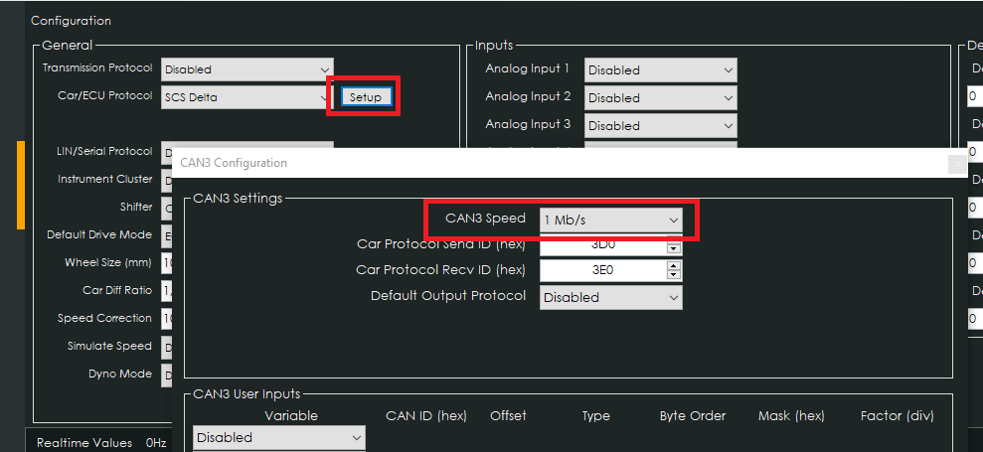

¶ SCS Delta CAN Configuration

Select a matching CAN speed/frequency in both SXTune and CANTCU Configurator.

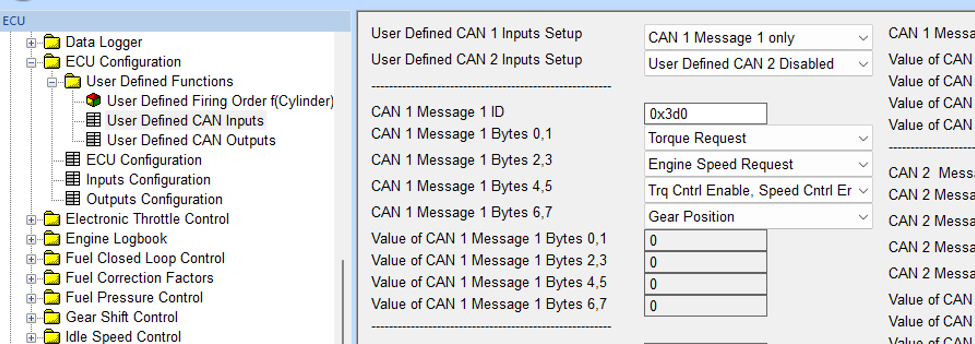

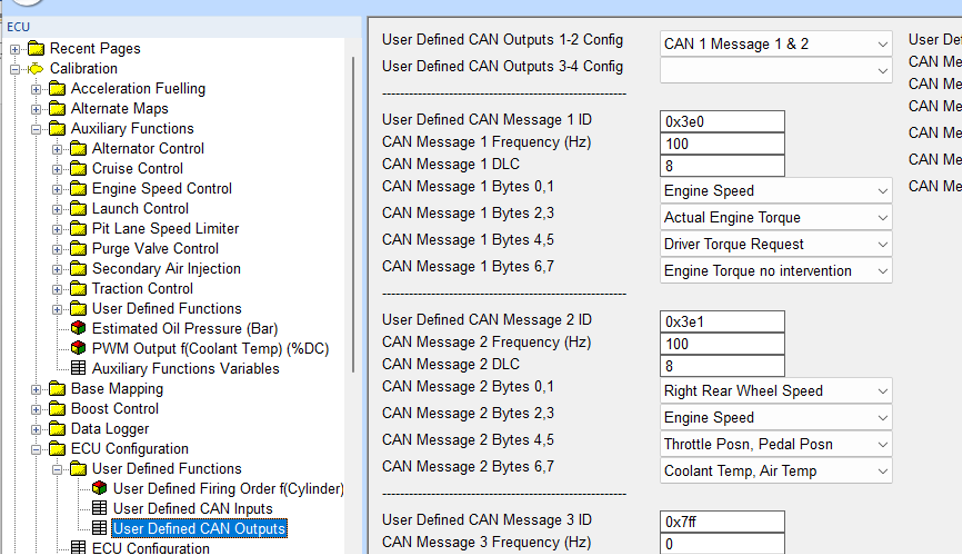

User defined CAN Inputs settings as below. Note that CAN 1 is selected, change to CAN 2 if required depending on which ECU CAN bus the CANTCU is connected to.

User defined CAN output settings as below. Note that CAN 1 is selected, change to CAN 2 if required depending on which ECU CAN bus the CANTCU is connected to.

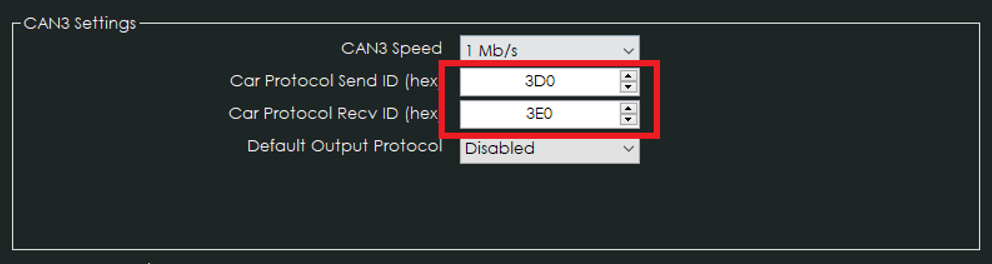

Match the CANTCU Send ID and Recv ID to IDs used in SXTune.

¶ Torque Management Settings

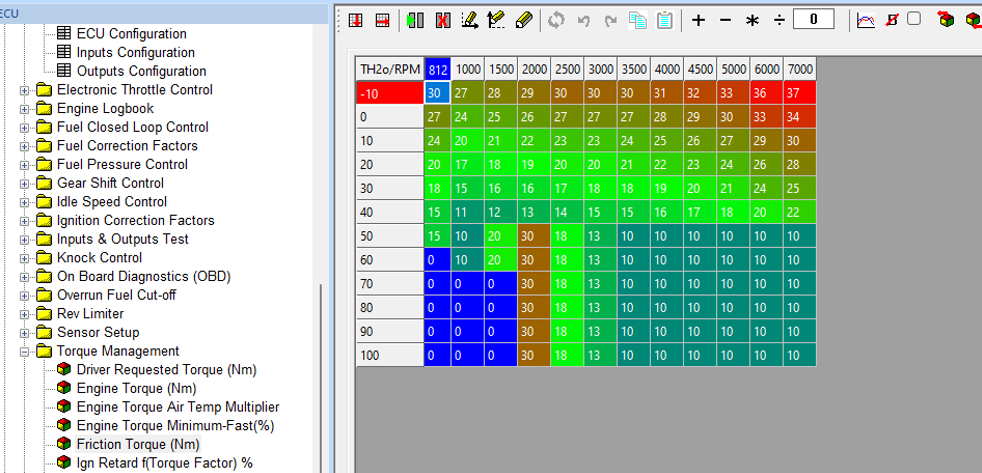

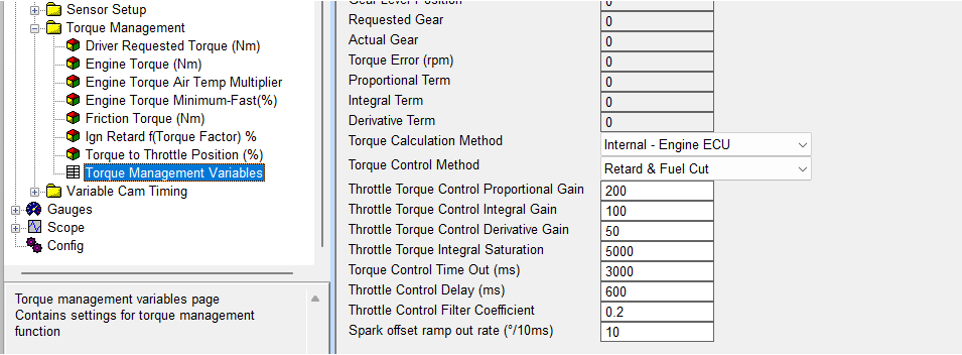

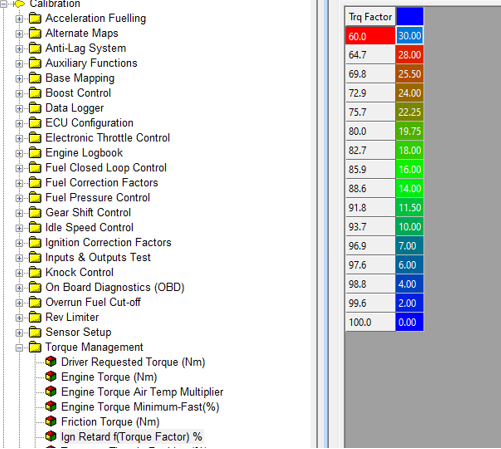

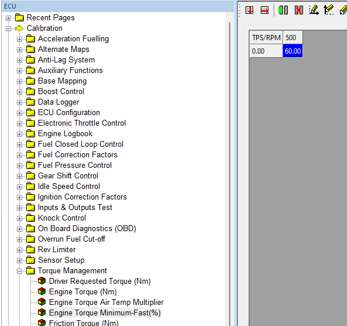

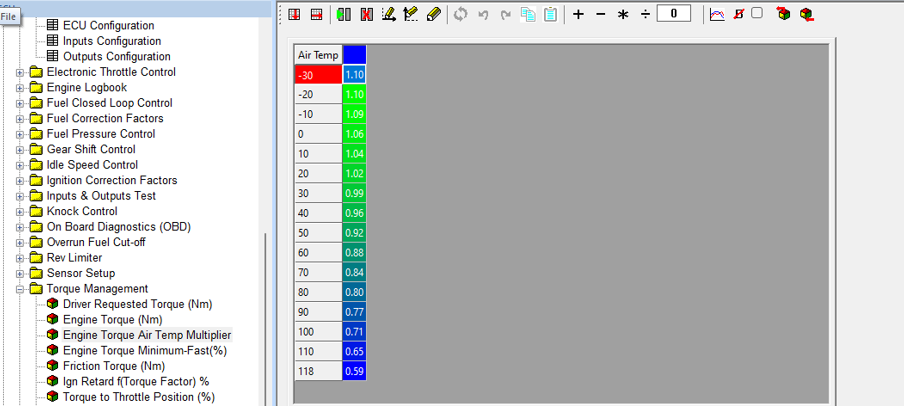

In Torque Management, set variables as below:

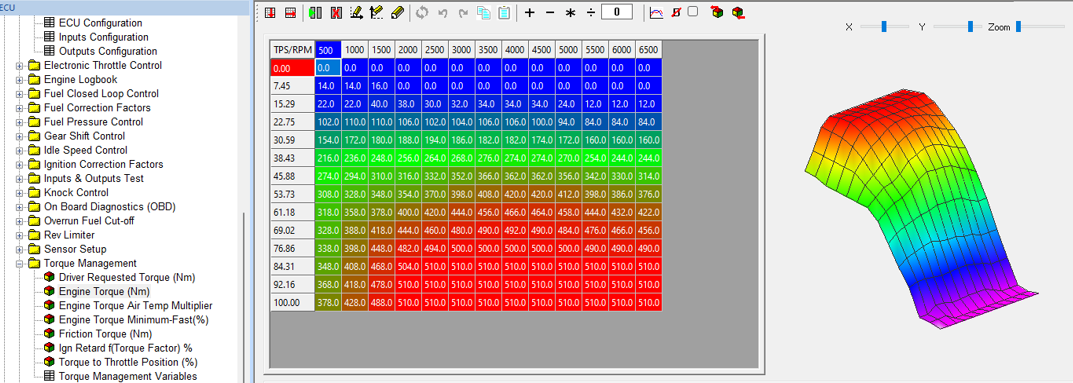

Example Engine Torque map. This map should be calibrated on a dyno or rolling road, and it can be estimated from a full load power curve. If transmission slip is experienced on low/medium load, increase the values in corresponding part of the map.

Ignition Retard f(Torque Factor) %. If torque reduction on upshifts feel too aggressive/excessive, decrease the values in this map.

Engine Torque Minimum-Fast(%)

Engine Torque Air Temp Multiplier

Friction Torque example map