CANTCU

Hardware

Integrations

- ECUs

- Dashes

- Drivetrain

Software

-

- Configuration

- Diagnostics

- Flashing

Installation Manual

Technical info

Transmissions

Transmissions

CANTCU CAN3 is connected to ECUMaster CAN-bus.

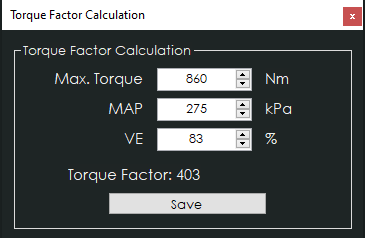

ECM Switch board of type CSB V3 0x640 needs to be enabled. CAN-bus speed/bit rate can be adjusted to suit project-specific requirements, default speed is 500kb/s.EMU Stream (CAN) needs to be enabled on the used CAN-bus. Base ID can be freely configured.To achieve a somewhat realistic torque estimation, the ECU VE (fuel) table needs to be tuned and show real-world VE-values. For this torque estimation we use a Torque Factor. The torque factor is generated from engine running values taken from a single point of running (usually maximum measured torque on a dyno run). The values needed for calculation are listed below.

Entering these values in the calculation window will generate a torque factor, which will be used as a baseline for torque calculations in the CANTCU.

Example of a calculated torque factor

Example of a calculated torque factor

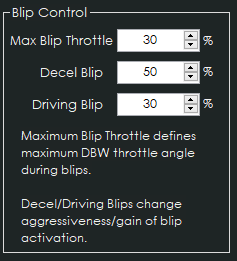

If CANTCU Blip Control strategy is used to control blips, the RT-value Throttle Blip is used as initial setpoint. Some extra adjustable parameters are available for fine tuning.

CANTCU Blip Control Settings

CANTCU Blip Control Settings